Unveiling the Hidden Flavors: How Food X-ray Technology is Revolutionizing the Culinary World

Unlocking the secrets of flavors has always been a challenge in the culinary world. Chefs and food scientists have long searched for innovative ways to enhance and understand the taste profiles of ingredients. Now, thanks to the groundbreaking technology of food X-ray, a new era of gastronomical exploration has arrived. In this article, we delve […]

Ингредиенты

Unlocking the secrets of flavors has always been a challenge in the culinary world. Chefs and food scientists have long searched for innovative ways to enhance and understand the taste profiles of ingredients. Now, thanks to the groundbreaking technology of food X-ray, a new era of gastronomical exploration has arrived. In this article, we delve into the fascinating world of food X-ray technology and how it is revolutionizing the way we experience food.

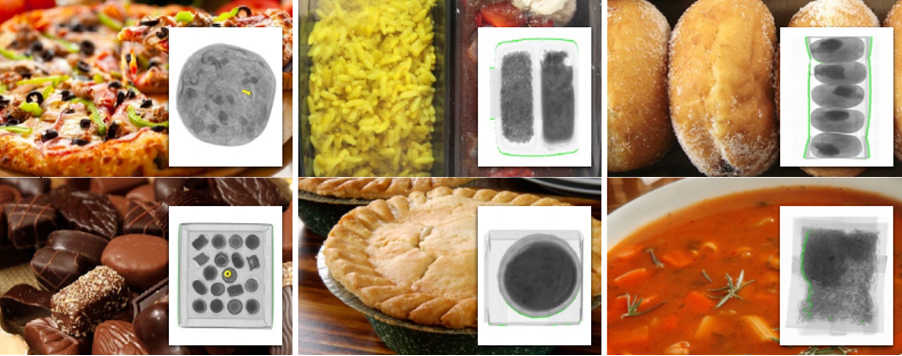

Using state-of-the-art X-ray machines specifically designed for food analysis, researchers can now visualize the internal structures of ingredients with unprecedented clarity. This allows them to uncover hidden flavors and textures that were once invisible to the human eye. By examining the molecular composition and density of various ingredients, chefs and scientists can gain valuable insights into how different cooking techniques and processes impact the taste and texture of food.

Food X-ray technology is not only changing the way we cook and eat but also providing invaluable information for manufacturers, enabling them to optimize their products and create appealing food options. Join us as we explore the incredible potential of food X-ray technology and its impact on the culinary landscape.

How food X-ray technology works

Food X-ray technology leverages the principles of X-ray imaging to inspect and analyze food products with remarkable precision. At its core, this technology utilizes high-energy electromagnetic radiation to penetrate food items, capturing detailed images of their internal structures. The X-ray machine emits radiation that passes through the food, and as it does, different components absorb the radiation in varying degrees. This differential absorption allows for a detailed visualization of the food’s internal composition.

The process begins with the food item being placed on a conveyor belt that moves it through the X-ray machine. As the food passes through, a digital detector captures the X-rays that emerge from the other side. This data is then processed by sophisticated software that constructs a high-resolution image of the product’s interior. The resulting image reveals a wealth of information, from the distribution of ingredients to the presence of foreign objects or contaminants. This capability not only aids in quality control but also provides insights into the food’s texture and composition.

One of the most fascinating aspects of food X-ray technology is its ability to identify hidden flavors and textures that often go unnoticed. By analyzing the molecular density and structural integrity of different components within the food, chefs and food scientists can uncover elements that contribute to the overall taste experience. This understanding allows for more informed culinary decisions, enabling the enhancement of flavor profiles through innovative cooking techniques and ingredient combinations.

Benefits of using food X-ray technology in the culinary industry

The culinary industry stands to gain immensely from the integration of food X-ray technology. One of the primary benefits is the ability to enhance food safety. By examining the internal structures of food products, manufacturers can detect foreign objects such as metal fragments, glass shards, or even stones that may pose a risk to consumers. This capability not only protects public health but also helps maintain brand integrity by preventing costly recalls and damage to reputation.

Another significant advantage is the optimization of flavor profiles. With detailed insights into the composition of ingredients, chefs can experiment more confidently with cooking techniques. For instance, understanding how different ingredients interact at a molecular level can lead to the discovery of new flavor combinations or cooking methods that enhance the overall dining experience. This innovation allows chefs to push the boundaries of traditional cuisine and offer unique dishes that captivate diners.

Moreover, food X-ray technology contributes to the consistency and quality of food products. By ensuring that each batch meets specific standards and contains the right balance of ingredients, manufacturers can produce high-quality items that meet customer expectations. This consistency is particularly crucial in a competitive market where consumers are increasingly discerning about the food they consume. With food X-ray technology, culinary professionals can elevate their offerings while minimizing waste and inefficiencies.

Applications of food X-ray technology in food processing and quality control

Food processing facilities are increasingly adopting X-ray technology as part of their quality control measures. The ability to conduct non-destructive testing means that food items can be examined without compromising their integrity. This application is particularly beneficial for bulk products, where visual inspection alone may not be sufficient. The technology can detect inconsistencies in size, shape, and internal structure, ensuring that only products meeting quality standards reach consumers.

In addition to quality control, food X-ray technology plays a crucial role in compliance with food safety regulations. Regulatory agencies mandate stringent checks to prevent contamination and ensure the safety of food products. By integrating X-ray inspection into their processes, manufacturers can demonstrate compliance with these regulations and provide evidence of their commitment to food safety. This not only reduces the risk of fines or penalties but also enhances consumer confidence in the brand.

Furthermore, the technology is instrumental in process optimization. By analyzing how food products behave during processing, manufacturers can identify bottlenecks or inefficiencies in their operations. For example, X-ray imaging can reveal how ingredients blend during mixing or the degree of doneness in cooked products. This information allows for adjustments to be made in real-time, leading to improved productivity and reduced operational costs.

Enhancing food safety with X-ray inspection

Food safety is paramount in the culinary world, and X-ray inspection technology significantly enhances safety protocols. With its ability to detect contaminants that are not visible to the naked eye, this technology serves as an essential tool for manufacturers and food processors. The detection of foreign objects, such as metal bits or plastic fragments, can be accomplished swiftly and accurately, minimizing the risk of harmful substances reaching consumers.

Moreover, X-ray technology can identify potential biological hazards, such as undeclared allergens. By examining the internal composition of food products, manufacturers can ensure that allergenic ingredients are not present in items that are marketed as allergen-free. This capability is especially important in an era where food allergies are on the rise, and consumers are increasingly vigilant about ingredient transparency. The ability to verify ingredient integrity fosters trust between consumers and brands.

Additionally, the use of X-ray inspection helps in monitoring the efficacy of cleaning and sanitation processes within food processing plants. Regular inspections can reveal residues or remnants from previous batches, allowing companies to take corrective actions promptly. This proactive approach not only aligns with best practices in food safety but also enhances the overall quality of the food produced.

Improving food quality and consistency with X-ray technology

The quest for high-quality food products is a driving force in the culinary industry, and food X-ray technology offers invaluable assistance in achieving this goal. By providing detailed insights into the internal structure of ingredients, chefs and manufacturers can ensure that they are using the best possible components for their culinary creations. This increased understanding of ingredient quality leads to better flavor profiles, textures, and overall dining experiences.

Moreover, the technology plays a crucial role in maintaining consistency across batches. In a restaurant setting, where the same dish must taste the same every time it is prepared, X-ray technology can aid in monitoring ingredient quality and proportions. By analyzing the density and composition of each batch of ingredients, chefs can make data-driven adjustments to recipes, ensuring that every dish meets the established standards of taste and presentation.

Furthermore, food X-ray technology supports the development of new products by allowing manufacturers to experiment with ingredient combinations and processing methods. By visualizing how different components interact at a molecular level, food scientists can innovate and create unique offerings that stand out in a crowded marketplace. This process of experimentation is key to pushing culinary boundaries and meeting evolving consumer preferences.

Increasing efficiency and reducing waste with food X-ray technology

In an industry that often grapples with inefficiencies and waste, food X-ray technology provides a pathway to improved operational performance. By enabling detailed analysis of food products, manufacturers can identify areas where resources are being underutilized or where processes could be streamlined. This insight leads to more efficient production methods, ultimately reducing costs and increasing profitability.

One of the notable ways that X-ray technology reduces waste is through improved sorting and grading of ingredients. The ability to detect imperfections or inconsistencies in raw materials allows manufacturers to separate high-quality ingredients from those that do not meet standards. This targeted sorting not only maximizes the use of premium ingredients but also decreases the likelihood of subpar products entering the market.

Additionally, X-ray technology facilitates better inventory management. By providing real-time data on the quality and composition of food products, manufacturers can make informed decisions about production schedules and inventory levels. This strategic approach minimizes overproduction and helps reduce food waste, contributing to more sustainable practices within the culinary industry. By combining efficiency with sustainability, food X-ray technology plays a critical role in shaping the future of food production.

Challenges and limitations of food X-ray technology

Despite its numerous benefits, food X-ray technology is not without challenges and limitations. One of the primary concerns is the initial investment required for the equipment and technology. For small-scale producers or independent restaurants, the costs associated with purchasing and maintaining X-ray machines may be prohibitive. This financial barrier can hinder widespread adoption, particularly in segments of the industry that could benefit the most from enhanced safety and quality control.

Another challenge lies in the interpretation of X-ray data. While the technology produces high-resolution images, understanding and analyzing these images requires specialized knowledge and expertise. Restaurants and food manufacturers must ensure that their staff is adequately trained to interpret the results effectively, which can involve additional time and resources. Without proper training, there is a risk of misinterpreting the data, potentially leading to incorrect conclusions about food quality and safety.

Additionally, X-ray technology has its limitations in terms of material detection. While it excels at identifying foreign objects and inconsistencies in density, it may struggle with certain materials, particularly those that are similar in density to the food being inspected. This limitation can present challenges in ensuring comprehensive safety checks, necessitating the use of complementary inspection methods. As the technology continues to evolve, addressing these challenges will be crucial for maximizing its effectiveness in the culinary industry.

Future developments and trends in food X-ray technology

The future of food X-ray technology looks promising, with ongoing advancements poised to enhance its capabilities further. One emerging trend is the integration of artificial intelligence (AI) and machine learning algorithms into X-ray analysis systems. By leveraging AI, food manufacturers can automate the interpretation of X-ray images, significantly reducing the time required for analysis and increasing accuracy. This evolution will make X-ray inspection not only more efficient but also more accessible for smaller producers.

Moreover, as consumer demand for transparency and sustainability increases, food X-ray technology is likely to adapt to meet these expectations. Future developments may focus on enhancing the technology’s ability to detect specific contaminants or allergens, providing more detailed insights into ingredient sourcing and quality. This capability will empower consumers to make informed choices while also supporting brands that prioritize transparency and food safety.

Additionally, advancements in X-ray technology itself may lead to more cost-effective solutions for smaller businesses. As the technology matures, we may see the introduction of more compact and affordable X-ray inspection systems designed specifically for smaller-scale operations. This democratization of technology will enable a broader range of food producers to harness the benefits of X-ray inspection, contributing to overall improvements in food safety and quality across the industry.

Conclusion: The impact of food X-ray technology on the culinary world

Food X-ray technology is undeniably transforming the culinary landscape, offering innovative solutions to some of the industry’s most pressing challenges. By unlocking hidden flavors and enhancing food safety, this technology empowers chefs and manufacturers to create higher-quality products while minimizing waste. With its ability to provide detailed insights into the internal structures of ingredients, food X-ray technology lays the groundwork for a new era of culinary exploration.

As the industry continues to evolve, the integration of X-ray technology will play a critical role in shaping the future of food production and consumption. From improving safety protocols to optimizing flavor profiles, the applications of this technology are vast and varied. As we look ahead, it is clear that food X-ray technology will remain at the forefront of culinary innovation, driving advancements that benefit both producers and consumers alike.

The journey of uncovering flavors and enhancing the culinary experience is far from over. With ongoing research and development, food X-ray technology will continue to push the boundaries of what is possible in the kitchen. As chefs and food scientists embrace this revolutionary tool, we can expect an exciting evolution in how we create, enjoy, and appreciate food in the years to come.

[addthis tool="addthis_inline_share_toolbox_eyrt"]